In the dynamic landscape of textile processing, Tolkar emerges as an industry leader, continually pushing boundaries with its cutting-edge solutions. This article delves into the innovative world of industrial garment dyeing, focusing on Tolkar’s state-of-the-art Industrial Garment Dyeing Machine. Explore the features that set Tolkar apart and the transformative impact it brings to the textile industry.

Tolkar’s Industrial Garment Dyeing Machine: Redefining Efficiency and Precision:

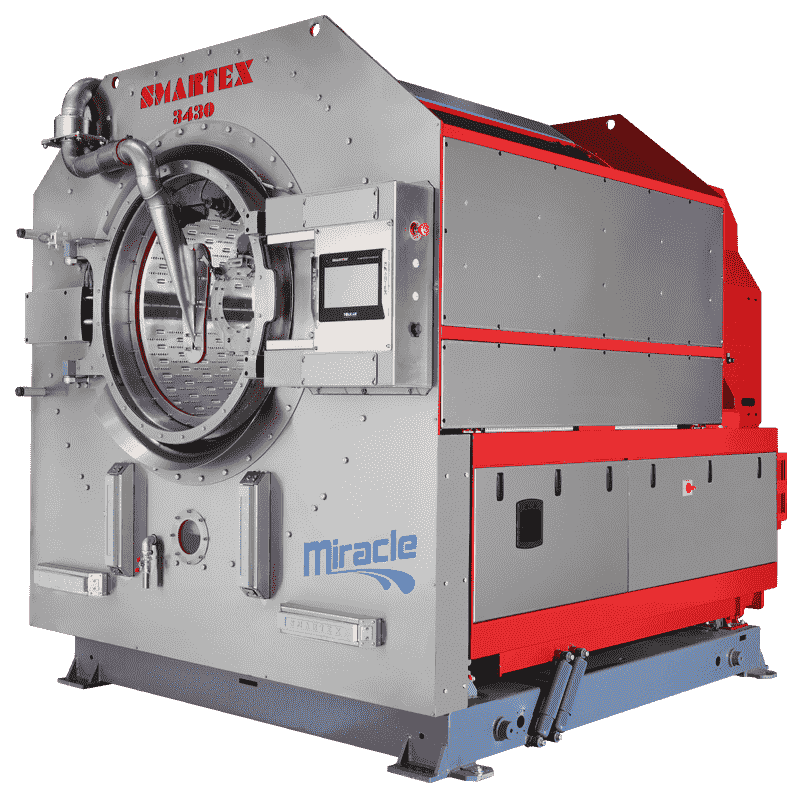

At the heart of Tolkar’s commitment to excellence lies the Industrial Garment Dyeing Machine – a sophisticated solution designed to revolutionize the textile dyeing process. This machine is engineered with precision and efficiency to meet the diverse needs of the textile industry.

Key Features of Tolkar’s Industrial Garment Dyeing Machine:

- Versatile Dyeing Capabilities: Tolkar’s machine stands out for its versatile dyeing capabilities, accommodating a wide range of fabrics and garments. From delicate textiles to heavy-duty workwear, this machine ensures uniform and vibrant color application, meeting the stringent standards of industrial dyeing.

- Precision Control and Automation: Leveraging advanced control systems and automation, Tolkar’s Industrial Garment Dyeing Machine offers unparalleled precision in the dyeing process. This level of control not only enhances the quality of the final product but also optimizes resource utilization, contributing to sustainable and cost-effective operations.

- Resource Efficiency: Tolkar prioritizes resource efficiency, integrating technologies that minimize water and energy consumption without compromising on the quality of the dyeing process. This eco-friendly approach aligns with Tolkar’s commitment to sustainable textile solutions.

Tolkar: Pioneering Innovation in Textile Technology:

With a legacy rooted in innovation, Tolkar has consistently been at the forefront of advancements in textile technology. The Industrial Garment Dyeing Machine exemplifies Tolkar’s dedication to providing solutions that elevate efficiency, reduce environmental impact, and redefine industry standards.

Global Impact and Industry Trust:

Tolkar’s influence extends globally, and its Industrial Garment Dyeing Machine has become a trusted choice for textile manufacturers worldwide. The seamless integration of technology and the commitment to delivering top-tier solutions have solidified Tolkar’s position as an industry trailblazer.

Conclusion:

Tolkar’s Industrial Garment Dyeing Machine represents a paradigm shift in textile dyeing, combining versatility, precision, and resource efficiency. As industries seek sustainable and high-performance solutions, Tolkar stands as a beacon of innovation, continually shaping the future of textile processing. Embrace the evolution with Tolkar – where technology and textiles converge for a brighter, more efficient tomorrow.

Tolkar’s Industrial Garment Dyeing Machine is noted for its versatile capabilities. How does the machine accommodate a wide range of fabrics, and what advantages does this versatility bring to textile manufacturers in terms of production flexibility?

Tolkar’s Industrial Garment Dyeing Machine accommodates various fabrics through its adaptable design and advanced technology. The machine’s versatility allows textile manufacturers to process different types of fabrics, providing production flexibility. This means manufacturers can efficiently dye anything from delicate textiles to heavy-duty workwear, meeting diverse market demands with a single solution.

Precision control and automation are highlighted as key features. How does Tolkar’s Industrial Garment Dyeing Machine ensure precision in the dyeing process, and what role does automation play in optimizing resource utilization during production?

Tolkar’s machine ensures precision through advanced control systems that regulate factors such as dye concentration, temperature, and processing times. Automation plays a pivotal role in optimizing resource utilization by managing these parameters with accuracy. This not only enhances the quality of the dyeing process but also contributes to sustainable operations by minimizing water and energy consumption.

Resource efficiency is a key focus for Tolkar. Could you elaborate on the technologies integrated into the Industrial Garment Dyeing Machine that contribute to minimizing water and energy consumption, and how does this align with Tolkar’s commitment to sustainability?

Tolkar’s machine integrates technologies such as low liquor ratio systems and energy-efficient heating mechanisms. These features minimize water and energy consumption during the dyeing process. Tolkar’s commitment to sustainability is reflected in the eco-friendly approach of the machine, ensuring that textile manufacturers can achieve their production goals while minimizing their environmental impact.

Tolkar is recognized for pioneering innovation in textile technology. How does the Industrial Garment Dyeing Machine exemplify Tolkar’s dedication to innovation, and what impact has it had on setting new industry standards in textile processing?

Tolkar’s Industrial Garment Dyeing Machine showcases Tolkar’s dedication to innovation by introducing advanced features that enhance efficiency, precision, and sustainability in textile processing. The machine’s impact on setting new industry standards is evident in its global adoption by textile manufacturers. Tolkar’s continuous pursuit of excellence has solidified its reputation as a trailblazer, influencing the future of textile processing on a global scale.