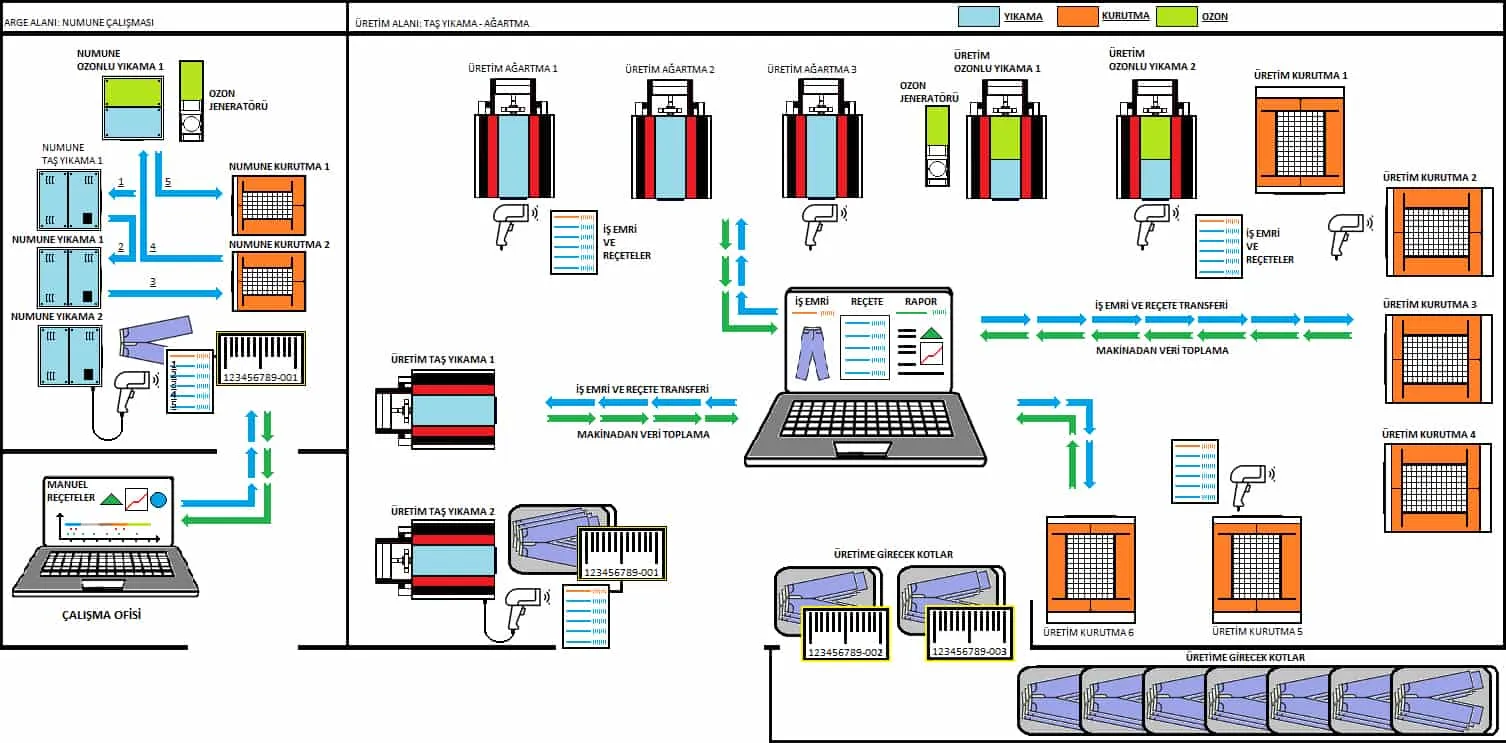

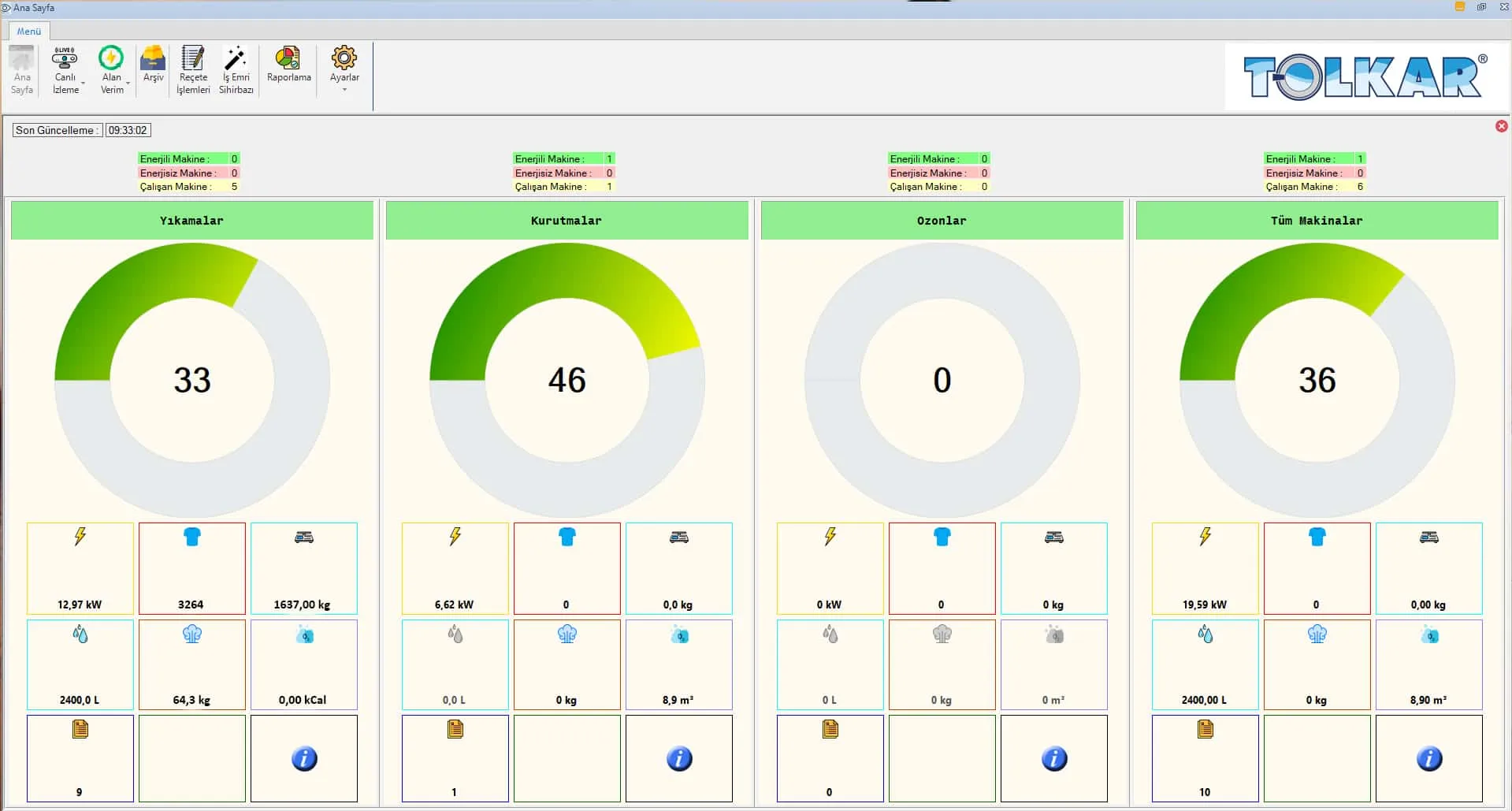

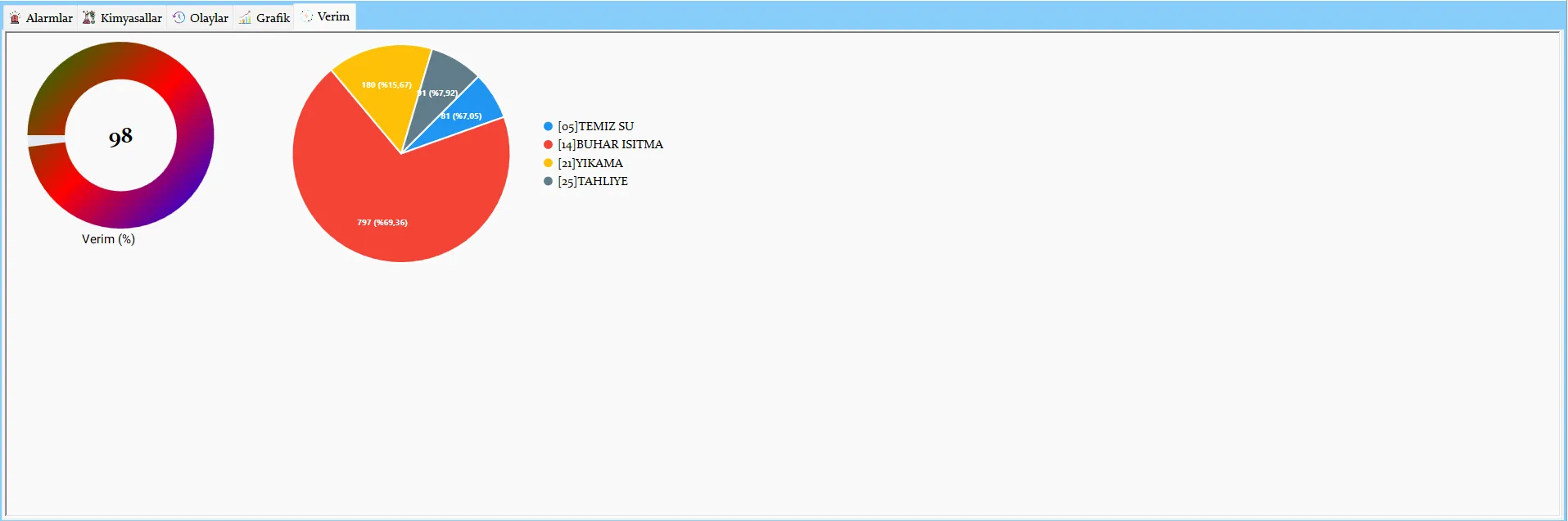

SmartEye is a SCADA automation that aims to compare the results obtained from production in the entire process from the first stage of production to the last stage. Our goals are:

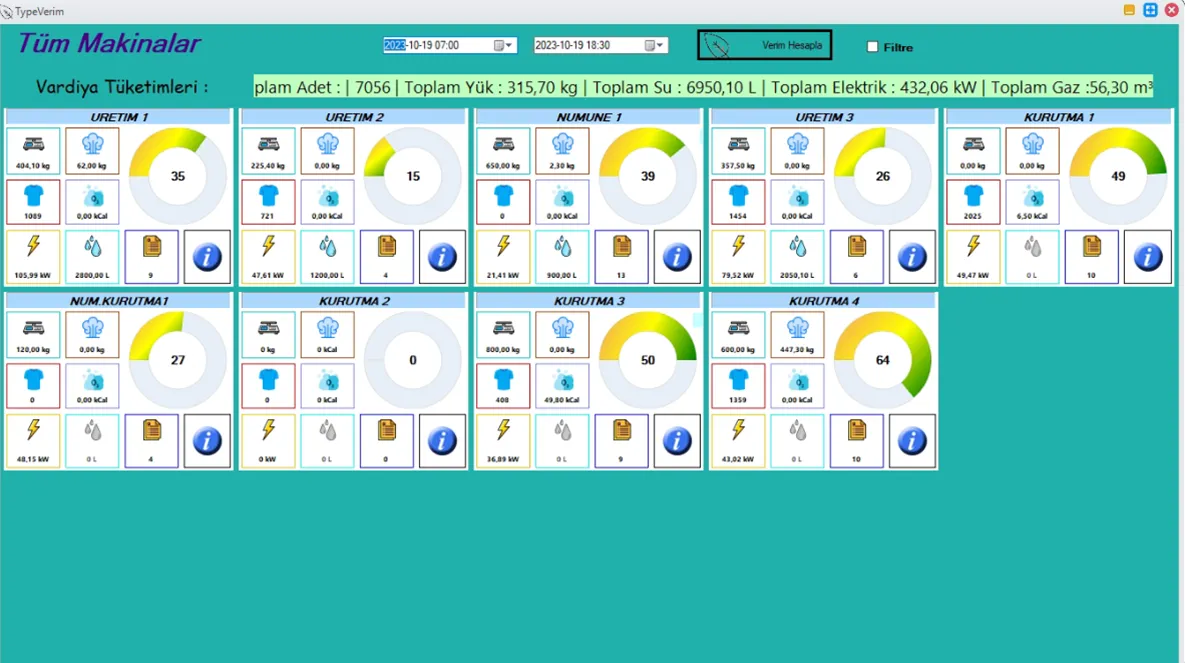

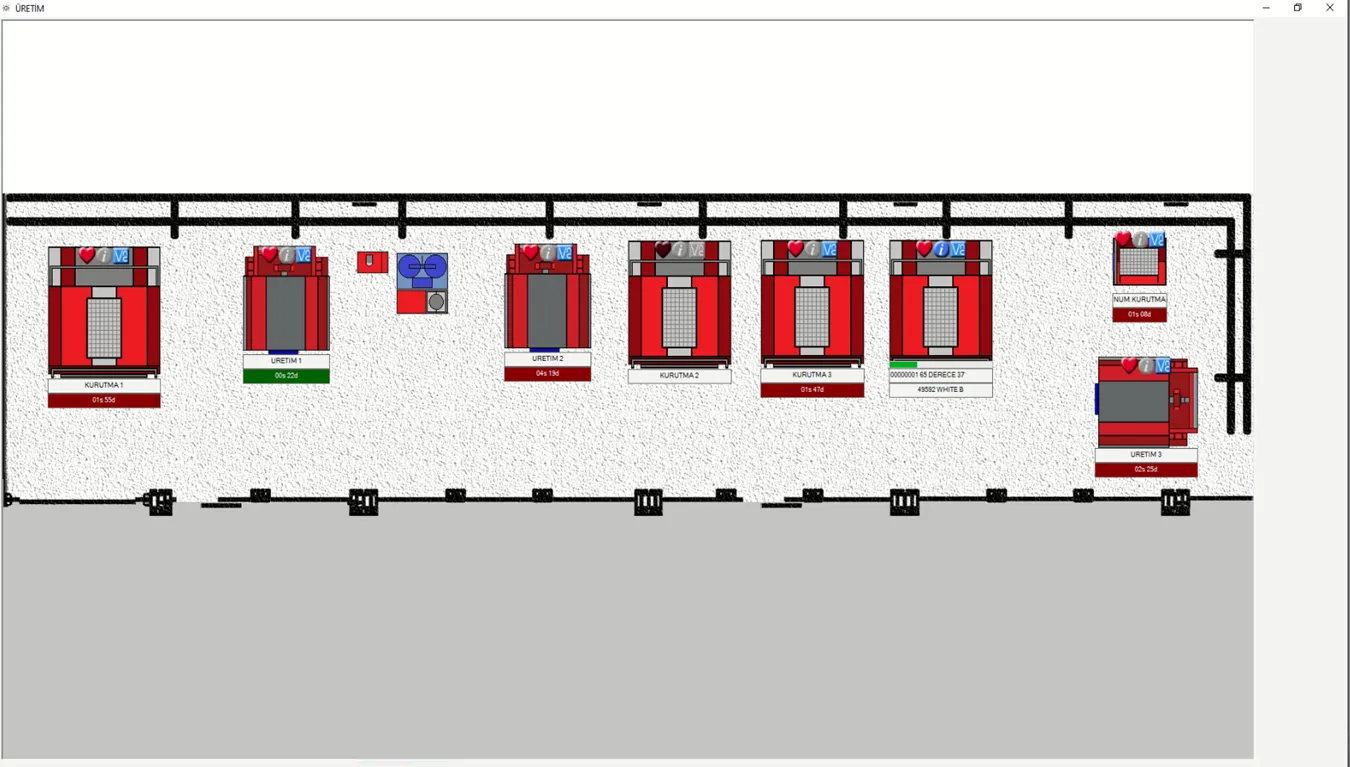

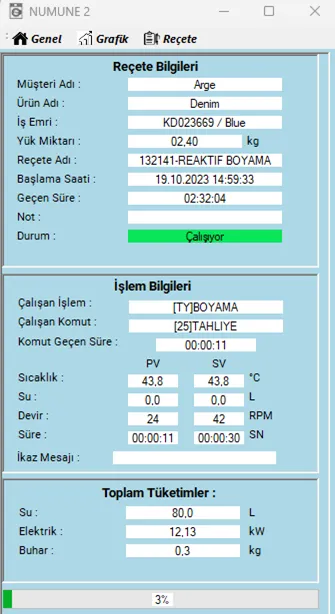

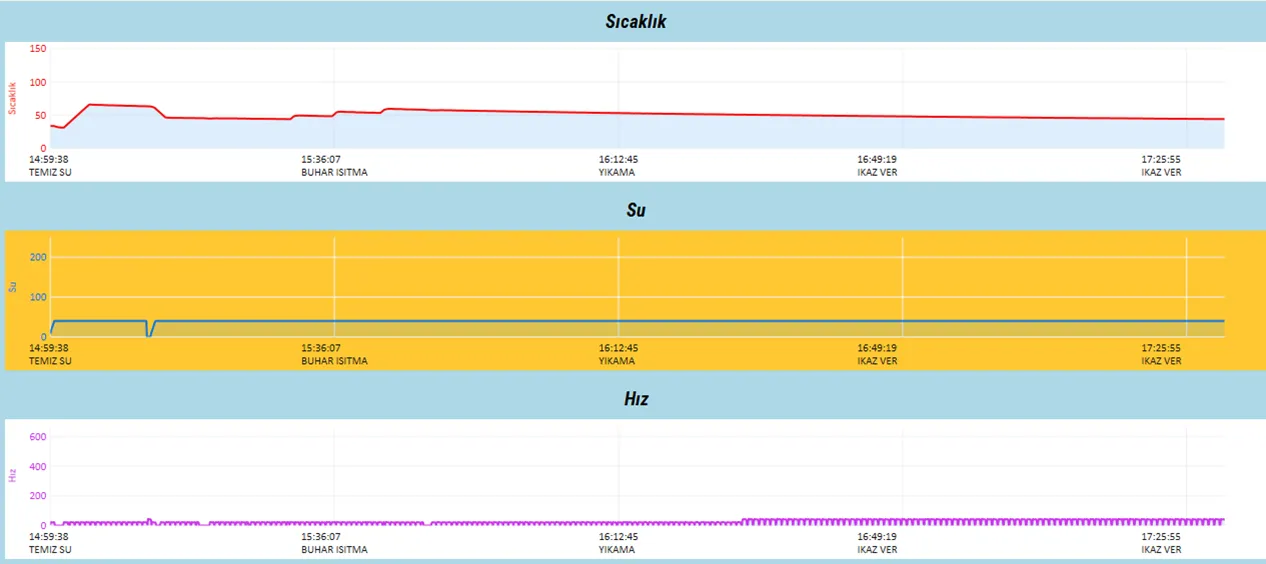

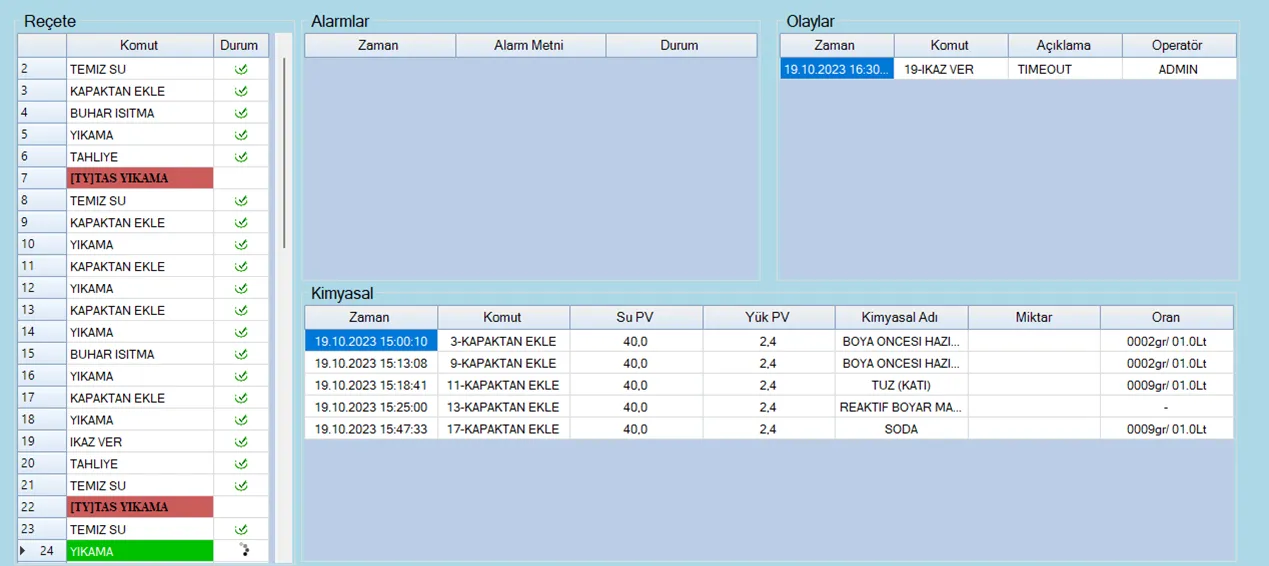

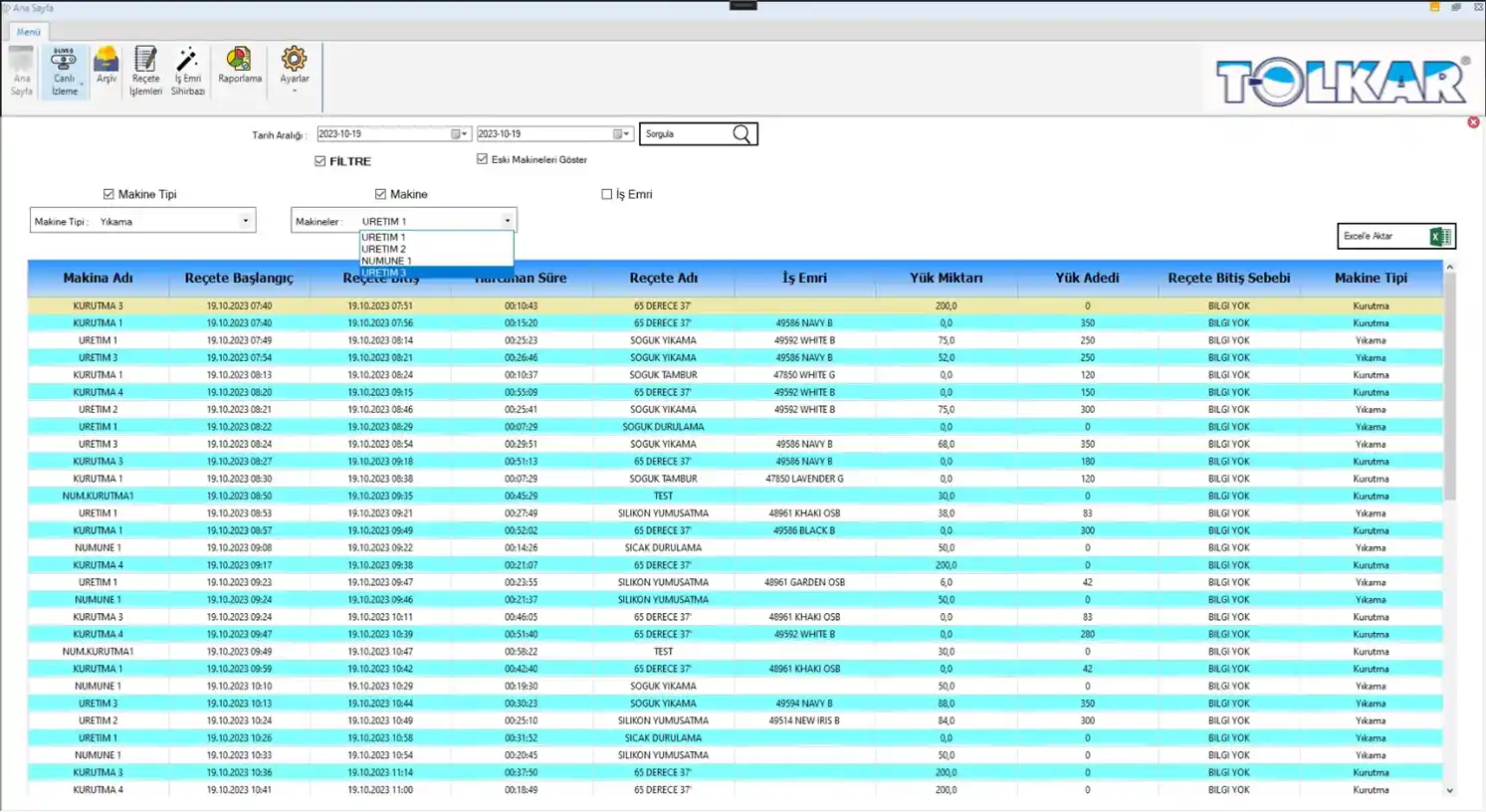

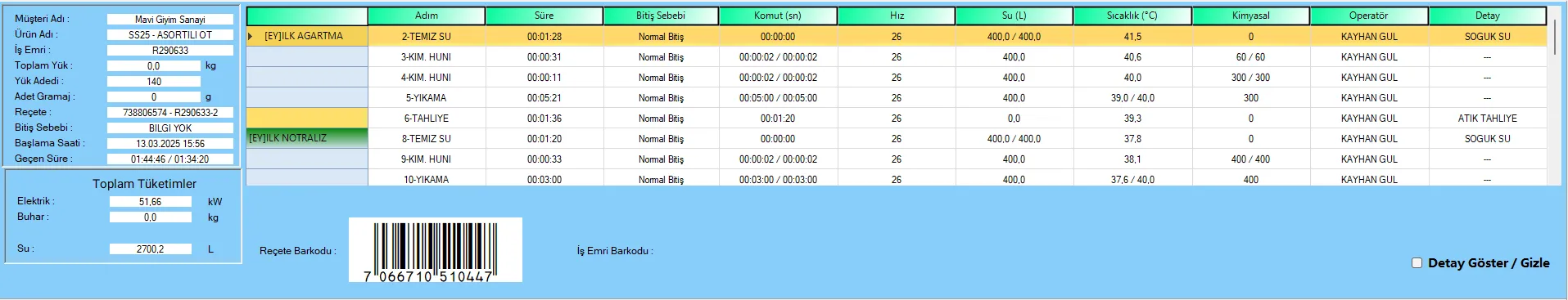

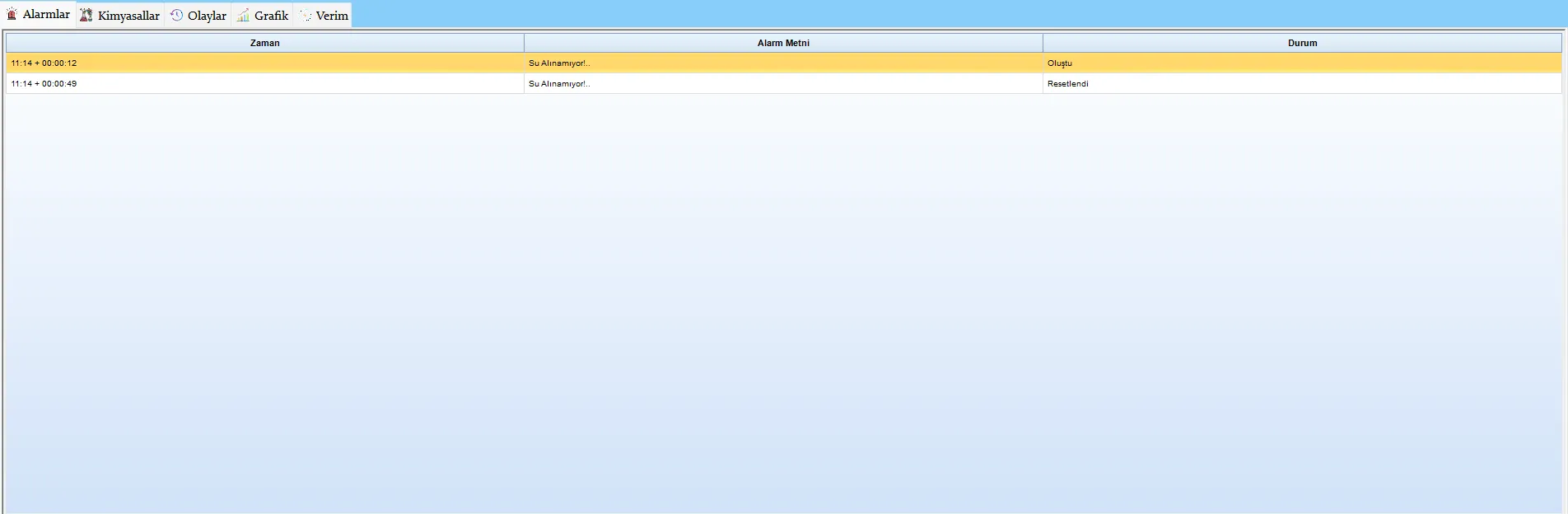

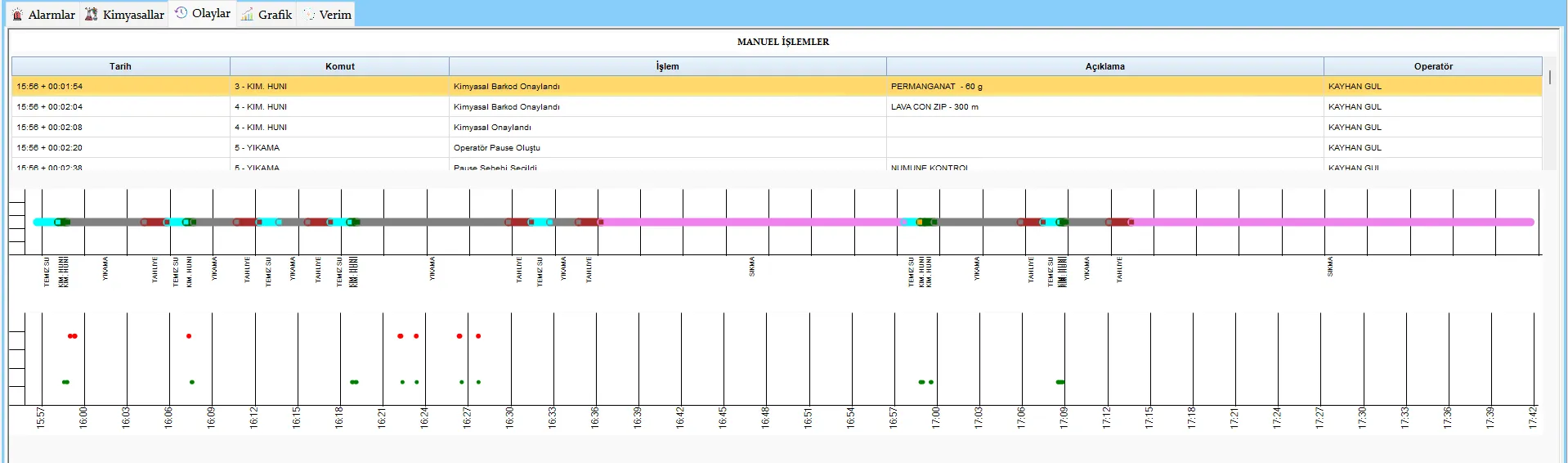

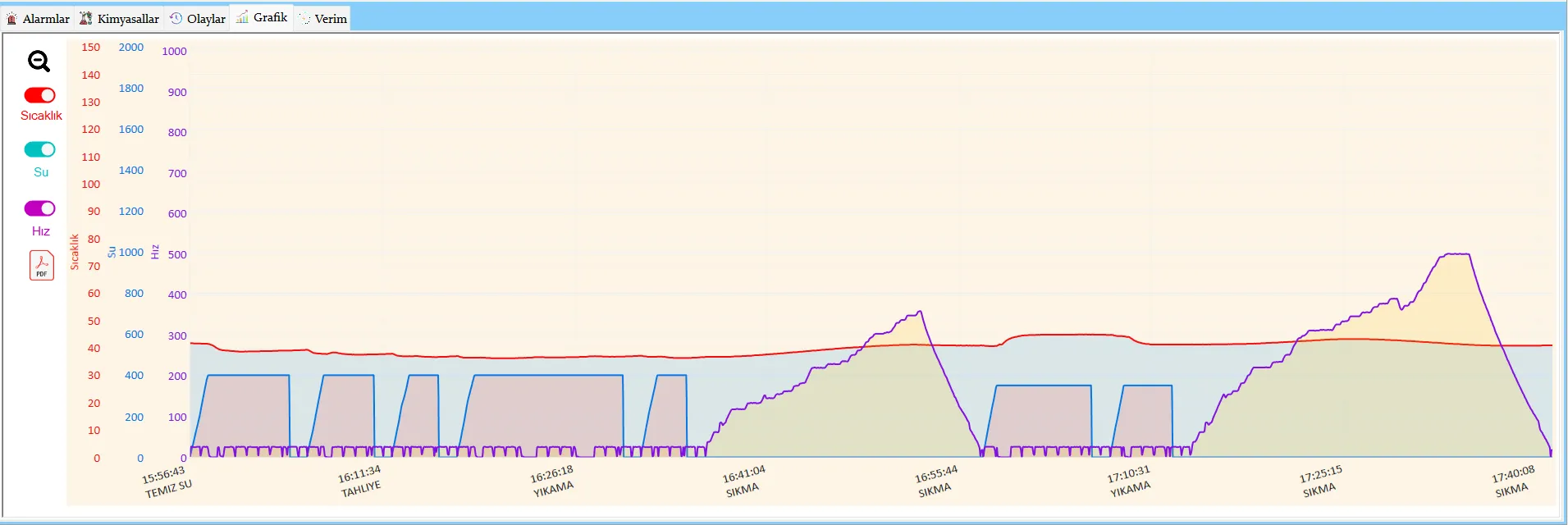

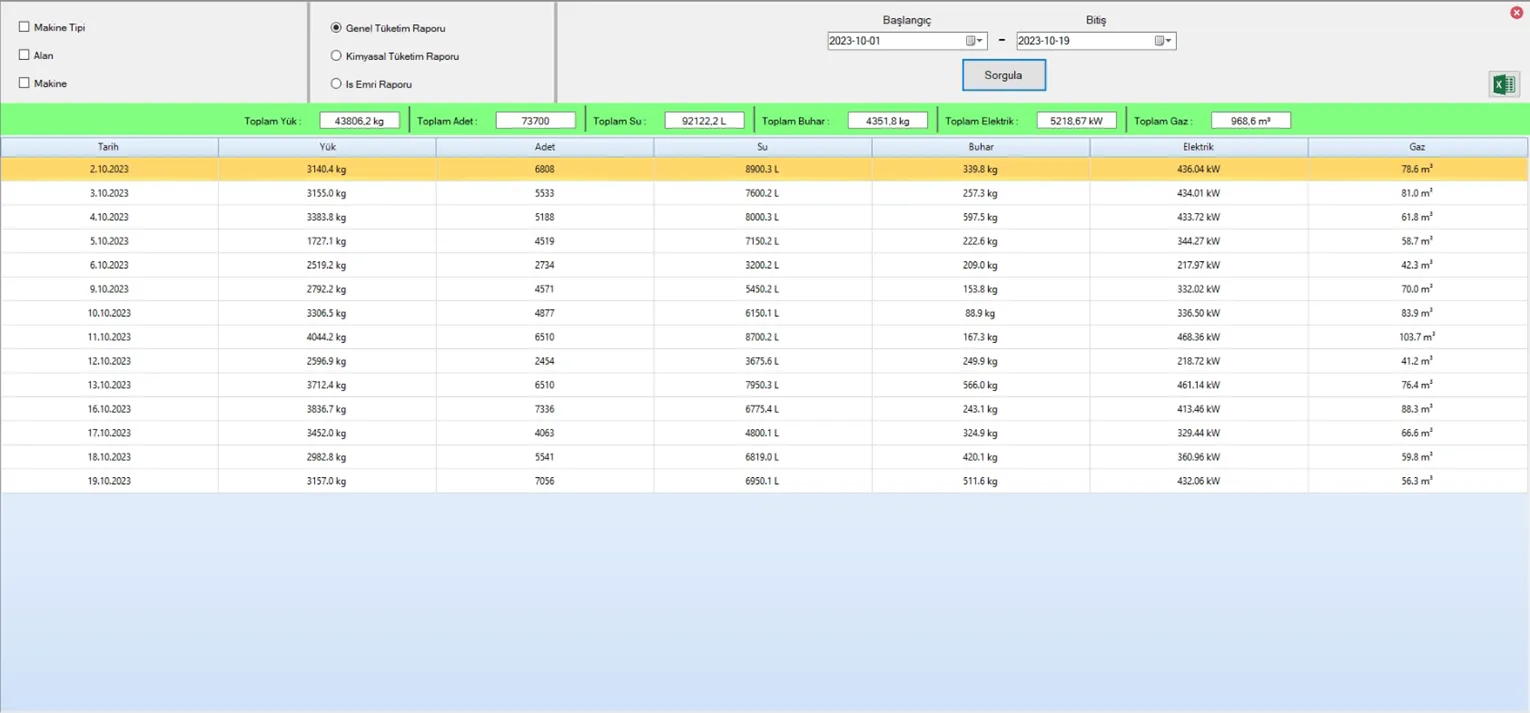

While the machines are running, SmartEye monitors all the machines connected to it. It displays and records many details such as the reasons for idle machines, stages of working machines, manual processes, operators at the machine, temperature – water – speed value graphs, etc. instantly. Each finished recipe is stored with a special label for easy access in the past.

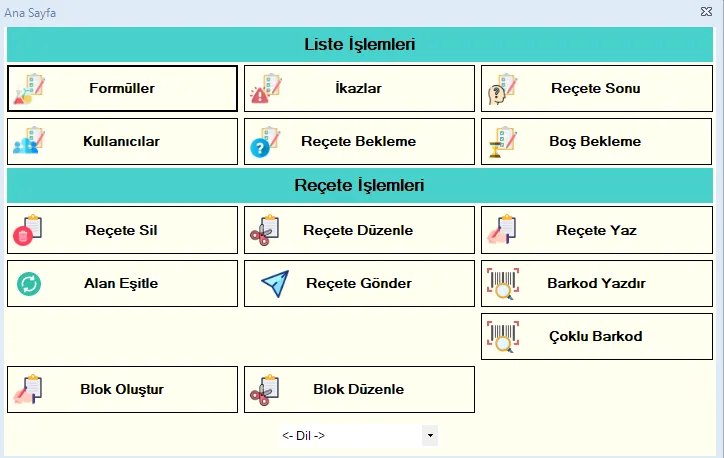

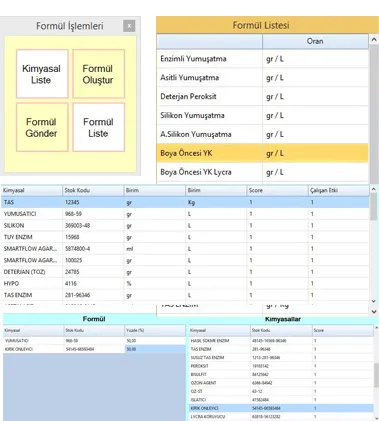

Functions of the Recipe Creating Module:

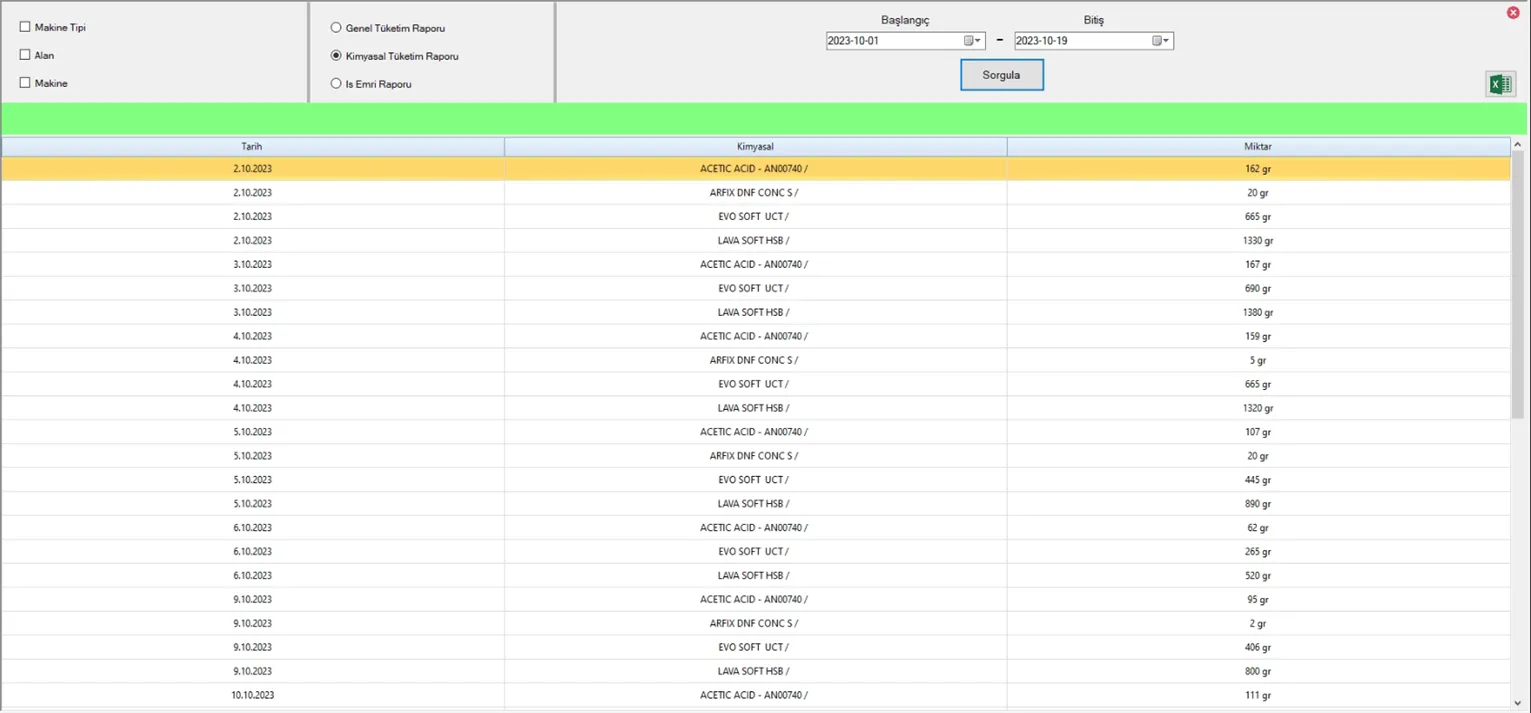

Formula creation procedures to use in commands containing chemicals in the recipe

Creating and editing warning lists on the panel

Creating and editing the end of recipe list on the panel

Creating and editing user lists in the panel

Creating and editing the list of pausing reasons on the panel

List of reasons for idle waiting on the panel creation, editing operations

Deleting existing recipes

Editing existing recipes

Recipe creating procedures

Alan eşitleme işlemleri

Sending existing recipes to machines

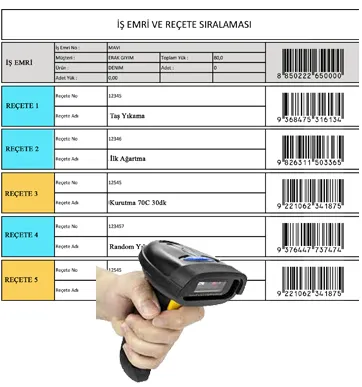

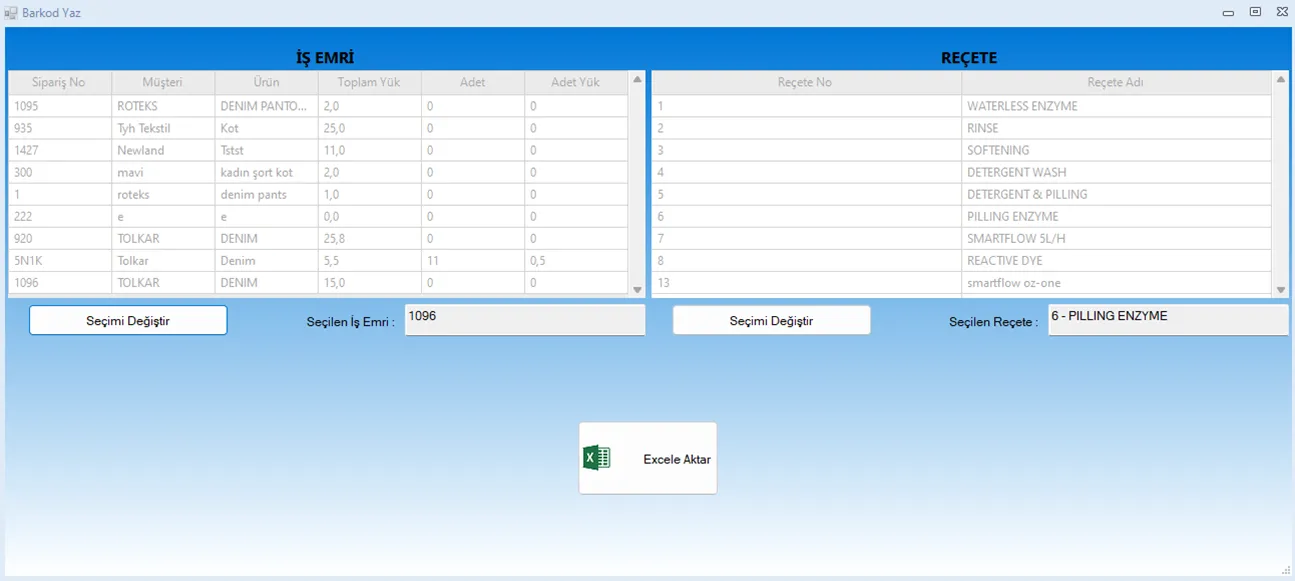

Barcode creation processes for prescriptions and work orders

Creating operations before starting the recipe to speed up the recipe writing process

Editing of previously registered operations

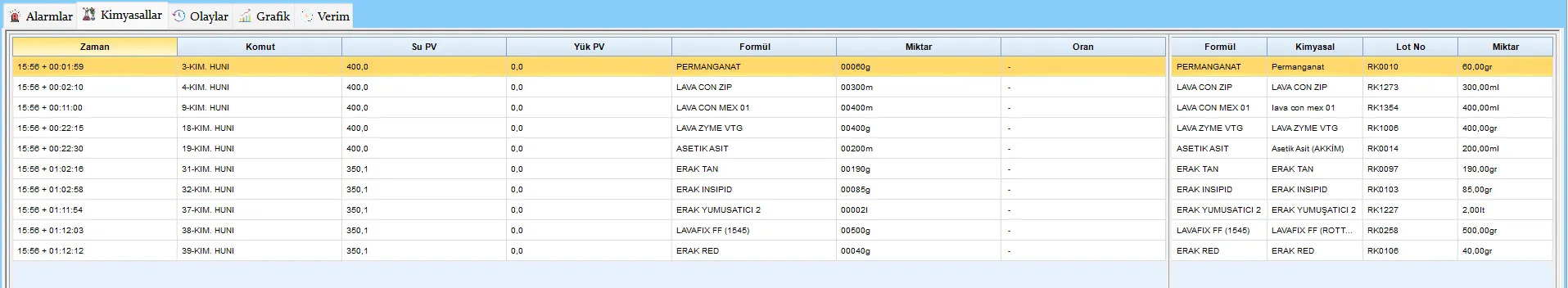

There is a chemical and formula library that can be created within SmartEye. If chemical selections are made from this library when writing a recipe, the chemicals are recorded by checking their accuracy with a barcode reader on the label before they are mixed into the products in the machine.

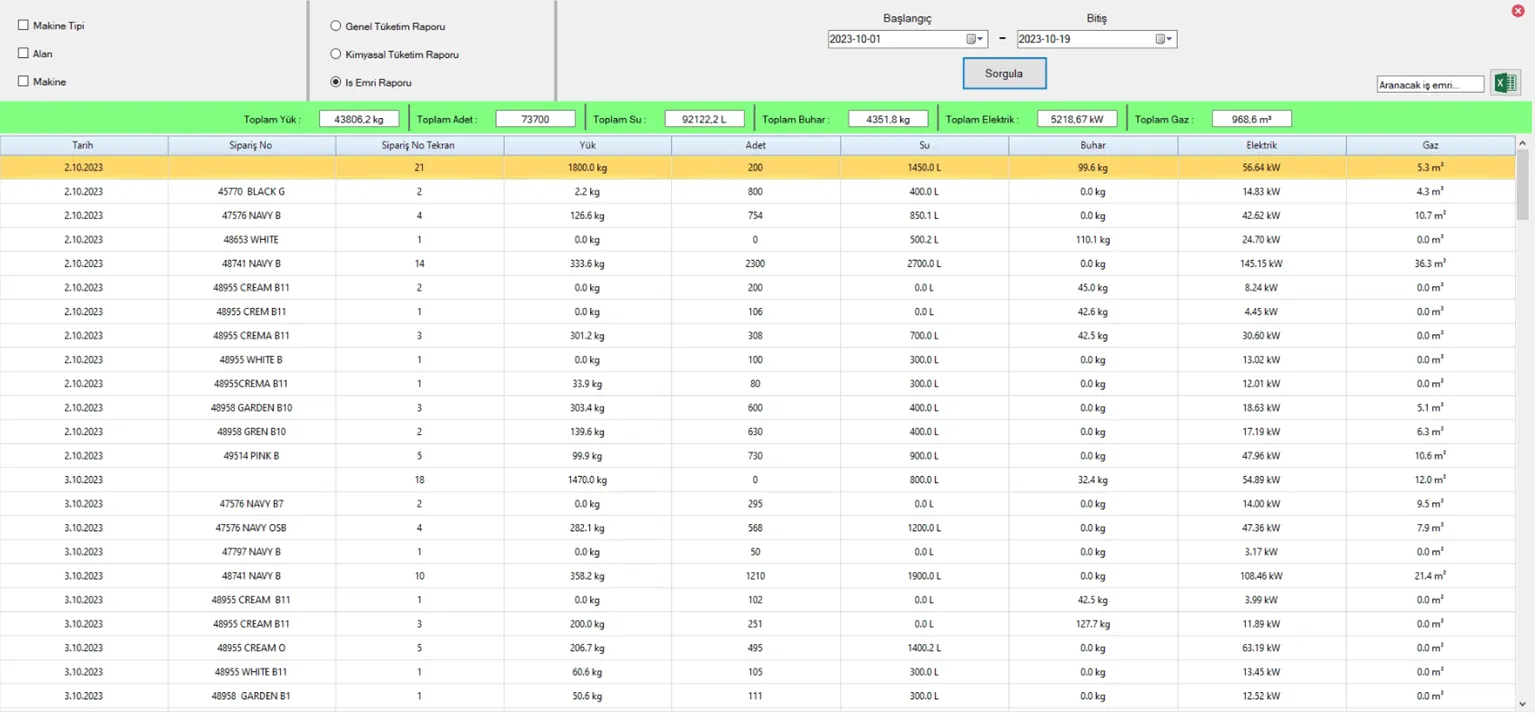

Pre-worked and sequenced recipe operations are easily written and recorded digitally on Tolkar SmartEye. Stone Washing – First Bleaching – 70 °C Drying – Random – Final Bleaching etc. are sent to the relevant machines in advance with the created recipes. Recipes carry a label representing themselves, just like work orders. When the product group comes to the machine, the work order and recipe label are read with the barcode reader and the right recipe is run on the machine screen for the right job.

The Work Order module;

It is the basic label that carries the general information of a job of 5-10 thousand units in sample work and 50-100 thousand units in production. Tolkar SmartEye job order label consists of 13 digits. The first 9 digits determine the Job Order, the next 3 digits determine the product or products to be washed or dried in the machine and in which order the product group is. It is valuable to see which machine and stage the product group is in during live monitoring and to record what is happening on the track.